Elastomers, also known as rubber, are crucial in everyday life as well as in the fields of mechanical engineering, mobility, aerospace, medical technology in the electrical industry and in the construction industry. The Giese group works on questions of elastomer chemistry, in particular the physical and chemical characterization, with the aim of optimizing polymer materials and their processing. This includes both raw materials and elastomers up to complex composite materials. Environmental aspects also play a special role.

Prof. Dr. Giese is head of the cooperating German Institute for Rubber Technology e. V. (DIK).

Development of electrode material for flowtrode electrodes

In order to shorten the time between the development of new drugs and their market launch, electrodes were developed in this project that combine high-resolution multimodal high channel electrophysiology (EEG) with microdialysis. By coupling these data, not only the time required for efficacy studies and the associated costs are reduced, but also the number of animal experiments required. The DIK subproject developed the material for the highly conductive electrodes consisting of a biocompatible silicone matrix (polydimethylsiloxane) and carbon nanotubes (CNT) as conductive filler.

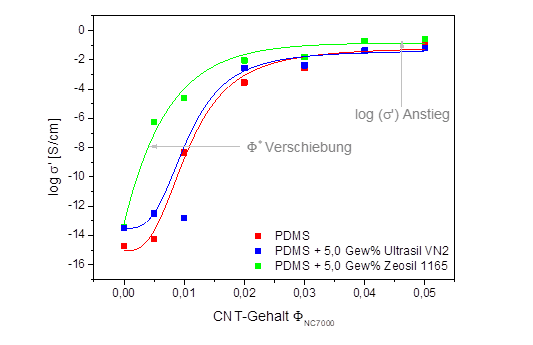

The requirements for the electrode material are to achieve an extremely high conductivity in order to transport neuronal signals while at the same time allowing the electrode to adapt to the anatomy of the brain. This was to be achieved by optimizing the dispersion of the CNTs, as this made it possible to drastically lower the percolation threshold (concentration from which conductivity exists). This reduction of the CNH concentration leads, as it were, to a minimization of the reinforcement associated with the addition of fillers, so that the electrode material is conductive and flexible at the same time.

Against the background of the high interparticular interactions of the CNTs and the associated tendency to form agglomerates, achieving optimum dispersion was a major challenge. In the course of the project, the mixing process was first optimized in order to break up the CNT agglomerates via mechanical forces. A further increase in dispersion could be achieved by using hybrid materials consisting of CNTs and silica as added fillers (Fig.). Subsequent processes for predispersion of the CNTs were able to lower the percolation threshold to 0.1 wt.% CNT. To ensure the toxicological safety of the electrode, it is still essential that the CNTs have good binding to the silicone. This was achieved by changing the polarity through surface functionality of the CNTs.

German Institute for Rubber Technology

The German Institute for Rubber Technology and the spin-off company together form the DIK with headquarters in Hanover. Both institutions cooperate closely in applied polymer chemistry with the Institute of Inorganic Chemistry through the personal union of Prof. Dr. Ulrich Giese. While the Testing Association is responsible for conducting tests and industrial contract research in the fields of polymer materials and plastics and rubber technology, the registered association is a non-profit, non-university, business-oriented research institution.